Greenlab Operation

A. Services:

01. ZDP-Zero Discharge Plan

02. IEE-Initial Environment Examination & SCCG-Site Clearance Certificate Guideline

03. EIA-Environment Impact Assessment

04. New ETP Plan & Design or Turn-key basis

05. ETP Correction & Monitoring with LAB Test

06. ETP Extension

07. Salt Recovery & UF-Ultra Filtration

08. NF-Nano Filtration

09. ROP-Reverse Osmosis Plant

10. EMP-Environment Management Plan

11. ZDP Execution

12. RG-Renewal Guideline

13. ECCG-Environment Clearance Certificate Guideline

14. ATP-Air Treatment Plant

15. STP-Sewerage Treatment Plant

16. WTP-Water Treatment Plant (Surface & Waste)

B. Products:

01. FP-Filter Press

02. AB-Air Blower

03. AD-Air Diffuser

04. WFM-Water Flow Meter

05. TP-Transfer Pump

06. DP-Dosing Pump

07. AM-Aeration Media

08. SF-Sand Filter

09. ACF-Activated Carbon Filter

10. SC-Scrapper for Clarifier

11. Agitator

12. OGS-Oil & Grease Separator

13. FPC-Filter Press Clothes

Effluent Treatment Plant (ETP)

Greenlab ECL provide all kinds of environmental consultancy regarding the Design and Drawing of Effluent Treatment Plant (ETP) for different industry like textiles, denim, paints, paper mills, pharmaceuticals, hospitals, steel mills, power industry etc. Greenlab ECL also consults about the correction as well extension of existing Effluent Treatment Plant (ETP). Greenlab ECL also provide ETP monitoring program where Greenlab ECL is responsible for controlling the parameter of ETP under the effluent discharge limit of ‘Environmental Conservation Rules, 1997′. Greenlab ECL always think about the latest technology, sustainable and high efficiency performances of ETP.

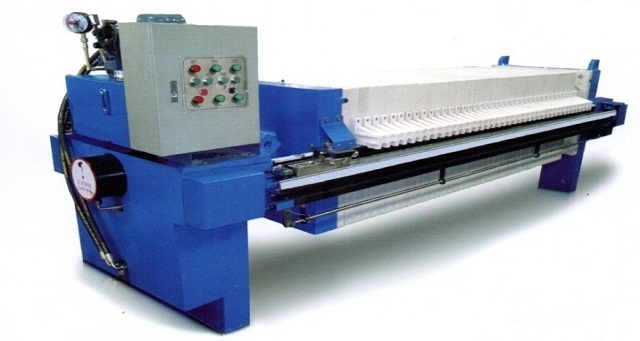

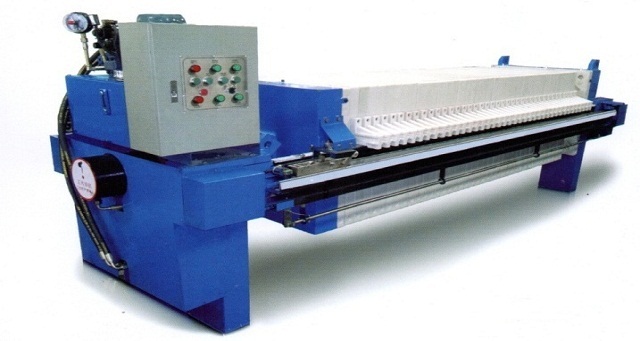

Filter Press for Sludge Management

One of the most difficult problems today is the disposal of sludge in wastewater treatment. Sludge de-watering using traditional de-watering systems or equipment (i.e. rotary vacum drum filters, centrifuges and belt presses etc.) are less acceptable for sludge disposal in landfills and due to their high moisture content they are not environmentally and economically feasible. The Filter Press Concept for Solid waste De-Watering and Management is a smart way of modern sludge handling of Effluent Treatment Plant (ETP) than any other conventional sludge de-watering method.

Reverse Osmosis Plant

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane. This membrane-technology is not properly a filtration method. In RO, an applied pressure is used to overcome osmotic pressure, a colligative property that is driven by chemical potential, a thermodynamic parameter. RO can remove many types of molecules and ions from solutions and is used in both industrial processes and in producing potable water. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be “selective,” this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as the solvent) to pass freely.

Sand Filter

Sand bed filters work by providing the particulate solids with many opportunities to be captured on the surface of a sand grain. As fluid flows through the porous sand along a tortuous route, the particulates come close to sand grains. Smaller sand grains provide more surface area and therefore a higher decontamination of the inlet water, but it also requires more pumping energy to drive the fluid through the bed. A compromise is that most rapid pressure sand bed filters use grains in the range 0.6 to 1.2 mm although for specialist applications other sizes may be specified. Larger feed particles (>100 micrometers) will tend to block the pores of the bed and turn it into a surface filter that blinds rapidly. Larger sand grains can be used to overcome this problem, but if significant amounts of large solids are in the feed they need to be removed upstream of the sand bed filter by a process such as settling. The depth of the sand bed is recommended to be around 0.6-1.8 m (2–6 ft) regardless of the application. This is linked to the maximum throughput discussed below. Guidance on the design of rapid sand bed filters suggests that they should be operated with a maximum flow rate of 9 m3/m2/hr.

Activated Carbon Filters

Activated carbon filters are generally employed in the process of removing organic compounds and/or extracting free chlorine from water, thereby making the water suitable for discharge or use in production processes.. Eliminating organics in potable water, such as humic and fulvic acid, prevents chlorine in the water from chemically reacting with the acids and forming trihalomethanes, a class of known carcinogens. Activated Carbon (AC) filtration, as with any water treatment method, is not capable of removing every possible type of contaminant. For example, sodium, microbes, fluoride, and nitrates cannot be removed with AC filtration. Water softening also cannot be achieved with AC filters. In addition, heavy metals, such as lead, can only be removed with a very specific kind of activated carbon water treatment, which is typically used only in residential point-of-use filters.

Coconut shells and coal (anthracite or bituminous) are both organic sources of activated carbon. Carbon forms when an organic source is burned in an environment without oxygen. This process leaves only about 30% of the organic mass intact, driving off heavy organic molecules. Prior to being used for water treatment, the organic mass must then be “activated.” The process of activation opens up the carbon’s massive number of pores and further drives off unwanted molecules. The open pores are what allow the carbon to capture contaminants, known as “adsorption”. The rate of adsorption for a surface area of a just one pound of AC is equal to 60-150 acres!

Laboratory Facilities:

Greenlab ECL, one of the country’s leading environmental laboratories, provides analytical services to clients throughout the whole country. Greenlab ECL has been providing its clientele with analytical laboratory services to support the client to control their discharging wastewater parameter under the Department of Environment (DoE) permitted range and various wastewater discharge monitoring programs, studies and special projects.

Greenlab ECL provides both sample collection services and analytical testing services. Greenlab ECL Laboratories’ Field Services staff is comprised of four, highly experienced, trained field technicians with extensive sampling capabilities.Greenlab ECL offers a wide array of analytical capabilities including methods:

- Biological Oxygen Demand (BOD)

- Chemical Oxygen Demand (COD)

- Total Suspended Solids (TSS)

- Total Dissolved Solids (TDS)

- pH

- Dissolved Oxyzen (DO)

Published on: Sunday, 16 April 2017, 09:56 am ▪ Last update: Sunday, 16 April 2017, 10:01 am ▪ Total View of this Page: 2143